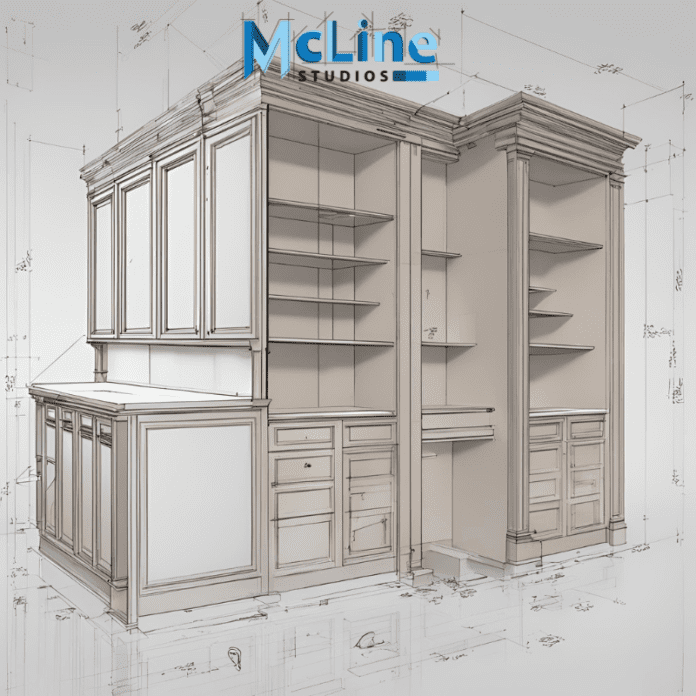

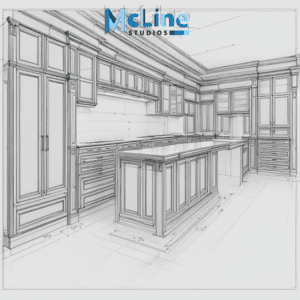

Millwork shop drawings serve as the blueprint for bringing intricate architectural millwork designs to life. In the world of construction and interior design, millwork plays a crucial role in adding elegance, functionality, and character to spaces. From custom cabinetry and ornate moldings to intricate staircases and decorative paneling, millwork encompasses a wide range of finely crafted woodwork and architectural elements.

These drawings serve as the visual roadmap, providing precise instructions and specifications for craftsmen, fabricators, and installers to follow. In essence, millwork shop drawings translate the creative vision of architects and designers into tangible, manufacturable components.

Overview of Millwork Shop Drawings

Millwork shop drawings represent a crucial component in the fabrication and installation process of architectural millwork. These detailed drawings serve as the primary communication tool between designers, architects, fabricators, and installers, providing precise instructions and specifications for crafting custom woodwork and architectural elements.

Components of Millwork Shop Drawings

Millwork shop drawings are detailed technical documents that serve as the blueprint for the fabrication and installation of custom millwork. These drawings are comprehensive and include various components to ensure accuracy and clarity in the manufacturing process. The main components of millwork shop drawings are:

1. Architectural Details

Dimensional Specifications: Precise measurements of each millwork component, including length, width, height, and depth. These dimensions ensure that every piece fits perfectly within the overall design.

Material Specifications: Information about the types of materials to be used, such as wood species, veneers, finishes, and any other relevant material characteristics. This ensures consistency in appearance and performance.

2. Elevations and Sections

Front Elevations: Drawings that show the front view of the millwork components. This includes details such as profiles, panel configurations, and decorative elements.

Side Elevations: Drawings that show the side view of the components, providing additional context and detail for complex shapes and structures.

3. Plans and Details

Floor Plans: Top-down views that show the placement and arrangement of millwork components within a room or space. These plans help ensure that all elements are properly aligned and coordinated with other architectural features.

Wall Plans: Detailed views of how millwork components attach to or integrate with walls, including attachment methods, backing requirements, and spacing.

4. Hardware and Accessories

Hardware Specifications: Detailed information about the hardware to be used, such as hinges, handles, drawer slides, and fasteners. This includes manufacturer specifications, model numbers, and installation instructions.

Accessory Details: Information about any additional accessories or decorative elements, such as moldings, trims, and decorative panels. These details ensure that all elements are included and properly installed.

5. Finishing Instructions

Surface Treatments: Specifications for any surface treatments, such as staining, painting, varnishing, or other finishes. This ensures that the final appearance meets the design intent.

Color and Texture: Information about the desired color and texture of the finished millwork, including samples or references to specific products.

6. Notes and Annotations

General Notes: Important information and guidelines that apply to the entire set of drawings, such as material handling instructions, safety considerations, and quality standards.

Specific Annotations: Detailed notes that apply to specific components or sections of the drawings, providing additional clarification and guidance for fabricators and installers.

7. Revisions and Version Control

Revision History: A log of all changes made to the drawings, including dates, descriptions of changes, and authorizations. This helps maintain accuracy and consistency throughout the project lifecycle.

Version Control: Clear identification of the current version of each drawing, ensuring that all stakeholders are working with the most up-to-date information.

Explaining the Process of Creating Millwork Shop Drawings

Creating millwork shop drawings involves several key steps to ensure precision and clarity in the final output. The process typically includes the following stages:

- Initial Consultation and Requirements Gathering

Meet with clients, architects, and designers to understand the project requirements and design.

Collect architectural plans, elevations, and any other relevant documents.

- Conceptual Design and Sketching

Develop preliminary sketches and concepts based on the gathered requirements.

Create rough drawings to visualize the basic design and layout of the millwork components.

- Drafting and Detailing

Use CAD or BIM software to create detailed 2D and 3D drawings.

Generate detailed elevations, sections, and plans to illustrate all aspects of the millwork components.

Ensure that all drawings comply with relevant building codes and standards.

- Review and Revision Process

Share the initial draft of shop drawings with clients, architects, and other stakeholders for feedback.

Make necessary revisions based on the feedback received.

Conduct multiple rounds of reviews and revisions to refine the drawings and address any discrepancies.

- Final Approval and Distribution

Obtain final approval from clients and relevant stakeholders.

Finalize the drawings, ensuring all details are accurate and complete.

Conclusion

Millwork shop drawings are essential in transforming architectural visions into tangible, manufacturable components that add elegance and functionality to spaces. These detailed technical documents serve as a crucial communication tool among designers, architects, fabricators, and installers, ensuring that every aspect of the millwork project is precisely executed.

In summary, millwork shop drawings are indispensable for the successful execution of custom millwork projects. They provide a clear roadmap for craftsmen and fabricators, translating the creative vision of designers into reality.

By ensuring accuracy, consistency, and quality, millwork shop drawings contribute significantly to the creation of aesthetically pleasing and functional architectural environments. The meticulous process of creating these drawings underscores their importance in achieving the highest standards of craftsmanship and design integrity in the millwork industry.